Complete Clock Spring Replacement (PICS)

I took the time to get the entire process in pictures complete with exact

tools. First and foremost, make sure the battery is disconnected. Attach the

two battery cables together. It helps to drain any residual voltage in the car

and prevent any accidental connections with the battery terminals.

small flat head screwdriver

Phillips #2 screwdriver

Rachet with 7,8,13 mm sockets and a 3-4" extension

2 torx bit sockets T25 and T50

Differential Bearing Puller vvv These guys vvv

You are also going to need the proper socket to turn the bolt on the pullers.

Ok tools gathered, and battery voltage gone, lets start working.

1) Remove two plugs on steering wheel back cover. They might be a bit of a

pain, but a small flat head can do it, just be patient.

2) Using the 8mm socket, remove the two air bag retaining bolts from behind

the plugs. The air bag module should start to slide out on its own. You can

pull it off the steering wheel, but dont yank on it. There is still the air

bag connector which needs to be removed.

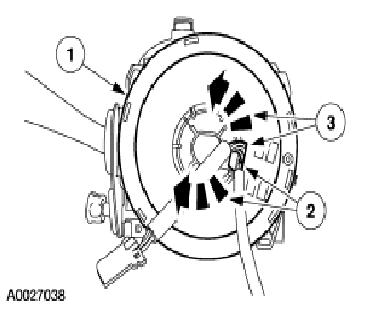

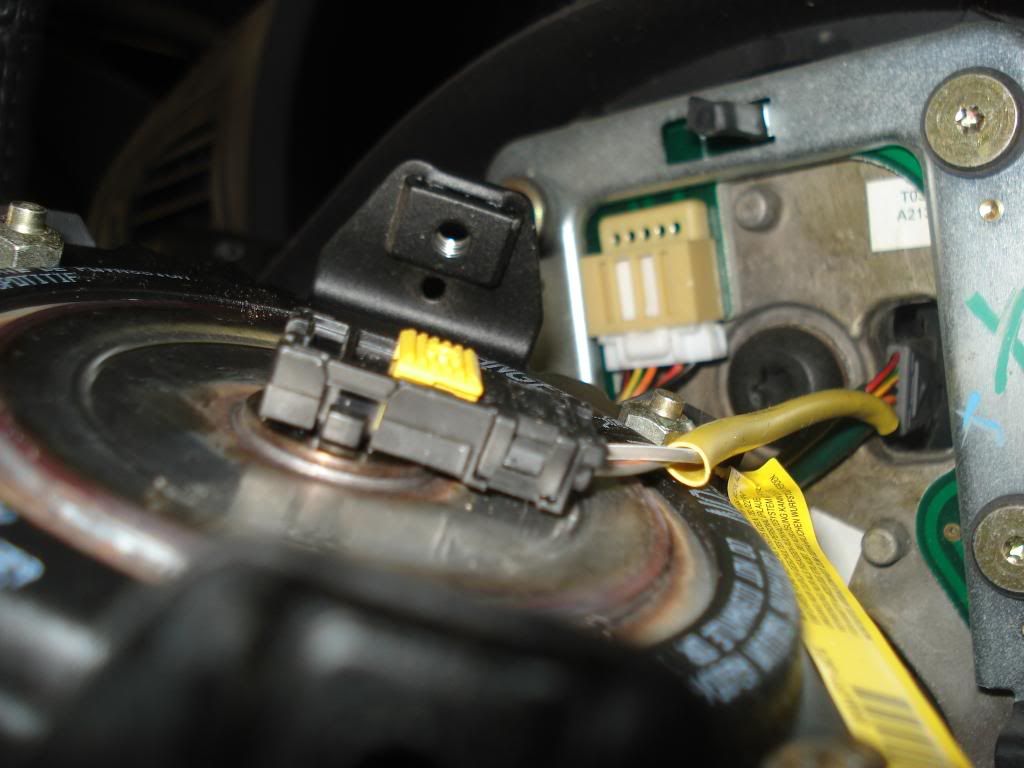

3) Slide the yellow tab towards back towards the wires and sqeeze the two

small black square tabs into the clip. I used both hands since they are so

small. When the clips are pushed together the connector can be pulled straight

back away from the module. Once off, you can go put the air bag somewhere

safe, remember to keep the Lincoln Star facing up

4) Remove the push pins from the bottom of the dash front, then pull of the

cover enough to disconnect the wires for the trunk release and fuel door.

5) Using the 7mm socket, remove the two screws holding the hood release in

place (i used a nut driver with the socket on it but the ratchet will work

perfectly)

6) Using the flat head screw driver (pliers would work well too) pry the two

push pins from the instrument insulator panel. Pull the panel most of the way

out, then remove the light by twisting counter clock wise.

7) Remove the 8mm screw holding the heater duct in place, then pull the heater

duct towards the drivers door and out.

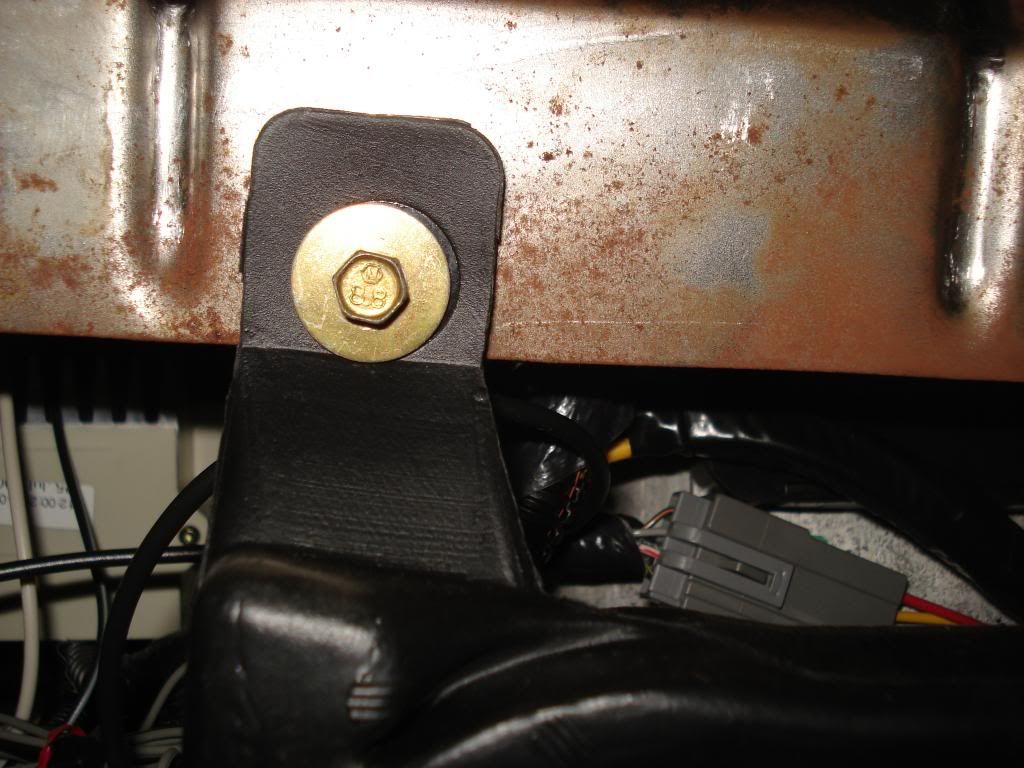

8) This step is in the Ford instructions, but I dont know the reasoning. I did

it, but I think it doesnt make a difference either way. Just under the center

console speaker is two 13mm bolts. Loosen but dont remove them cause they

arent fun to line back up in the holes. You will need to pull the carpet back

to access these bolts.

9) Remove the 5 screws in the steering column opening reinforcement panel.

Four of them are 8mm, and the one just to left of the steering column is 7mm.

OK, we are moving along nicely. Before you get any further make sure your

front wheels are straight and the steering wheel is centered. This is

important and without it the clock spring may not line up correctly.

10) There is four T25 torx screws in the steering wheel holding the horn

actuator on. Remove those bolts, but be careful, there is a spring behind each

one. Dont lose them. Gently move the green circuit card down and out of the

way. You can unplug the wires if you want, but its not neeed and the plugs are

pretty small. The big white connector in the center of the circuit board does

need to be removed.

11) Remove the steering wheel by first using the T50 torx socket to remove the

center bolt. It may be easier to have someone hold the steering wheel while

you break it free, but I got it free myself so a helper isnt necessary. Then

install the fingers of the bearing puller on the top and bottom of the

steering wheel frame. The center bolt on the puller should line up and fit

right where torx bolt went. If it does, then tighten the bolt down until the

steering wheel pops free. If it doesnt, then thread the torx back in a few

turns and center the puller bolt on it. Its more of a pain since the torx bit

will spin with the puller bolt. I only have a picture of the pullers on the

torx bolt, but i took it out before cranking down on the puller bolt.

12) Remove the two screws in the bottom of the steering column with a #2

phillips screwdriver, and pull down on the bottom part of the column. There

are plastic clips inside there, but I just pulled and it came free.

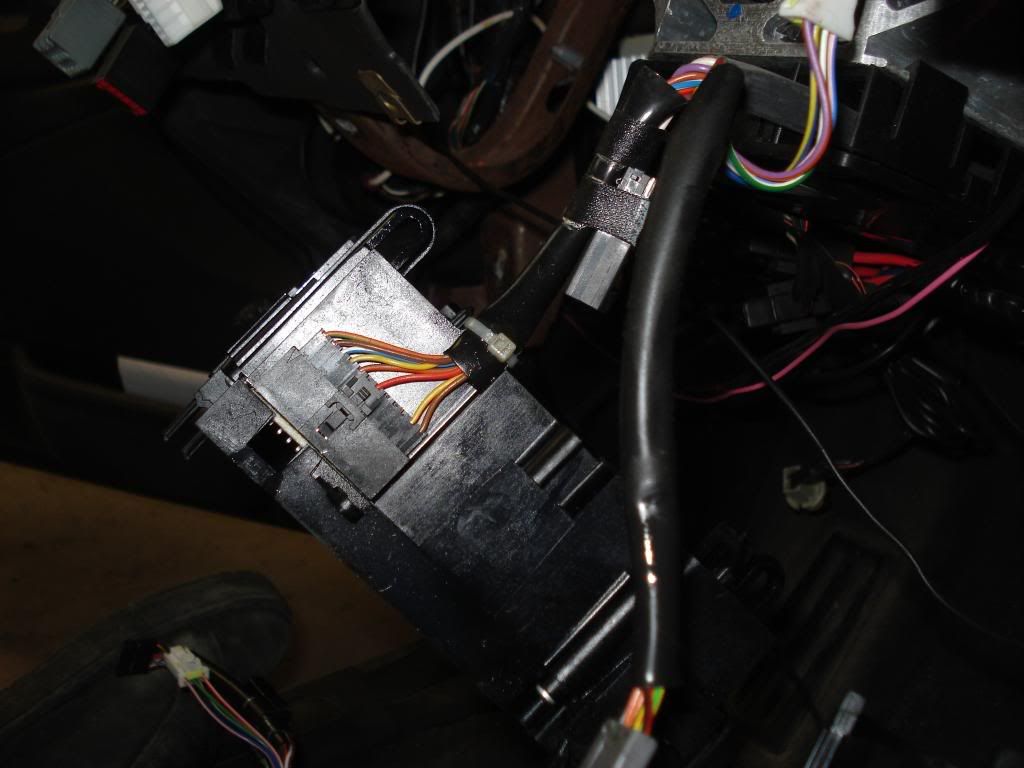

By now you should have clear access to the clock spring and all the

connectors. Everything is done by hand from her out.

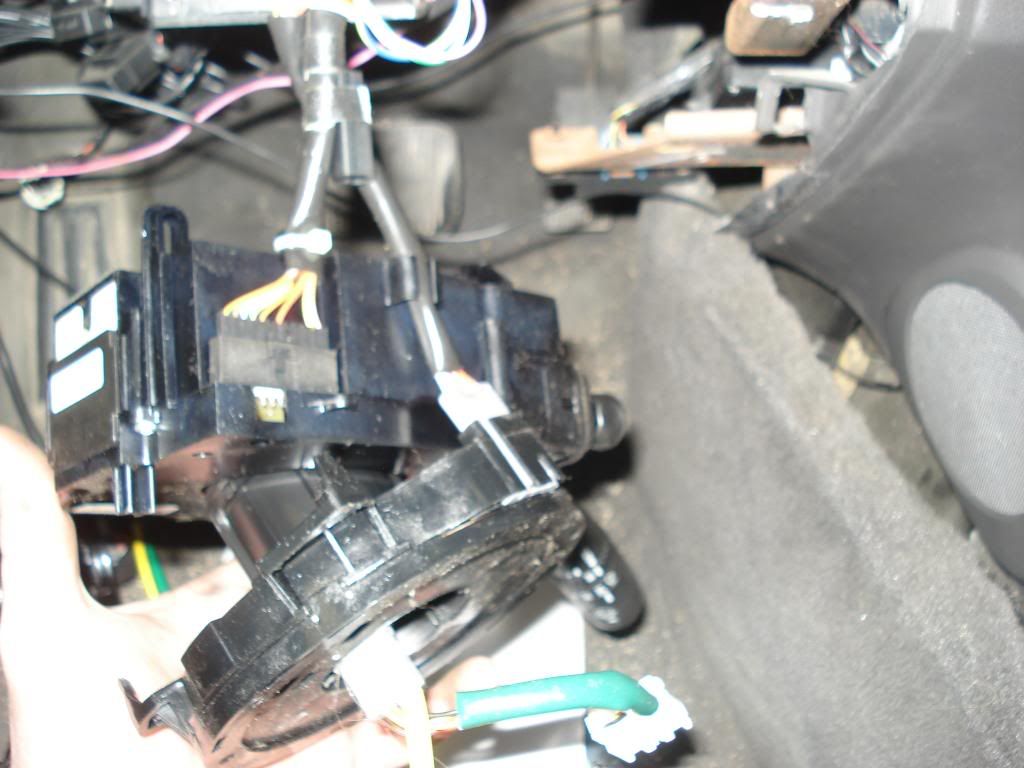

13) There are four clips holding the clock spring cylinder to the steering

wheel controls such as the wiper controls. First pull the two boxes straight

towards you and off the steering shaft. Then with your fingers (or a

screwdriver) pry the clips free so the clock spring comes free.

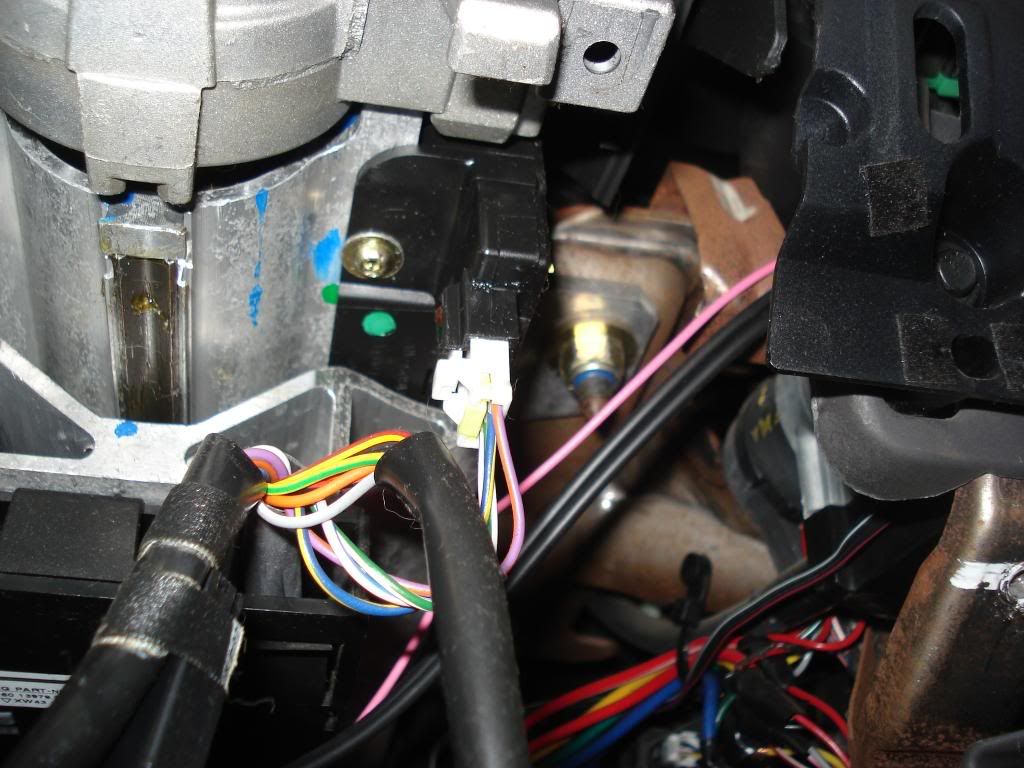

14) Remove all the connectors that go to/from the clock spring box (dont worry

about the wires on the cylinder)

cut the white wire tie in this picture to remove the long flat connector

15) Now you just have the four clips on the corners of the clock spring

holding it to the dash. Get the top two off and the bottom two will follow.

Ok, now the removal procedure is done. The new clock spring will have a

plastic key to keep it from rotating on you. Reverse the removal procedures

but wait until the clock spring cylinder is on the steering column before

pulling it off.